The KDR E-Save Drum Dryer is ideal for OEM compressor manufacturers.

Using the waste heat of the compressor (oil-flooded compressors) the KDR E-Save Drum Dryer uses no power and is easy to install.

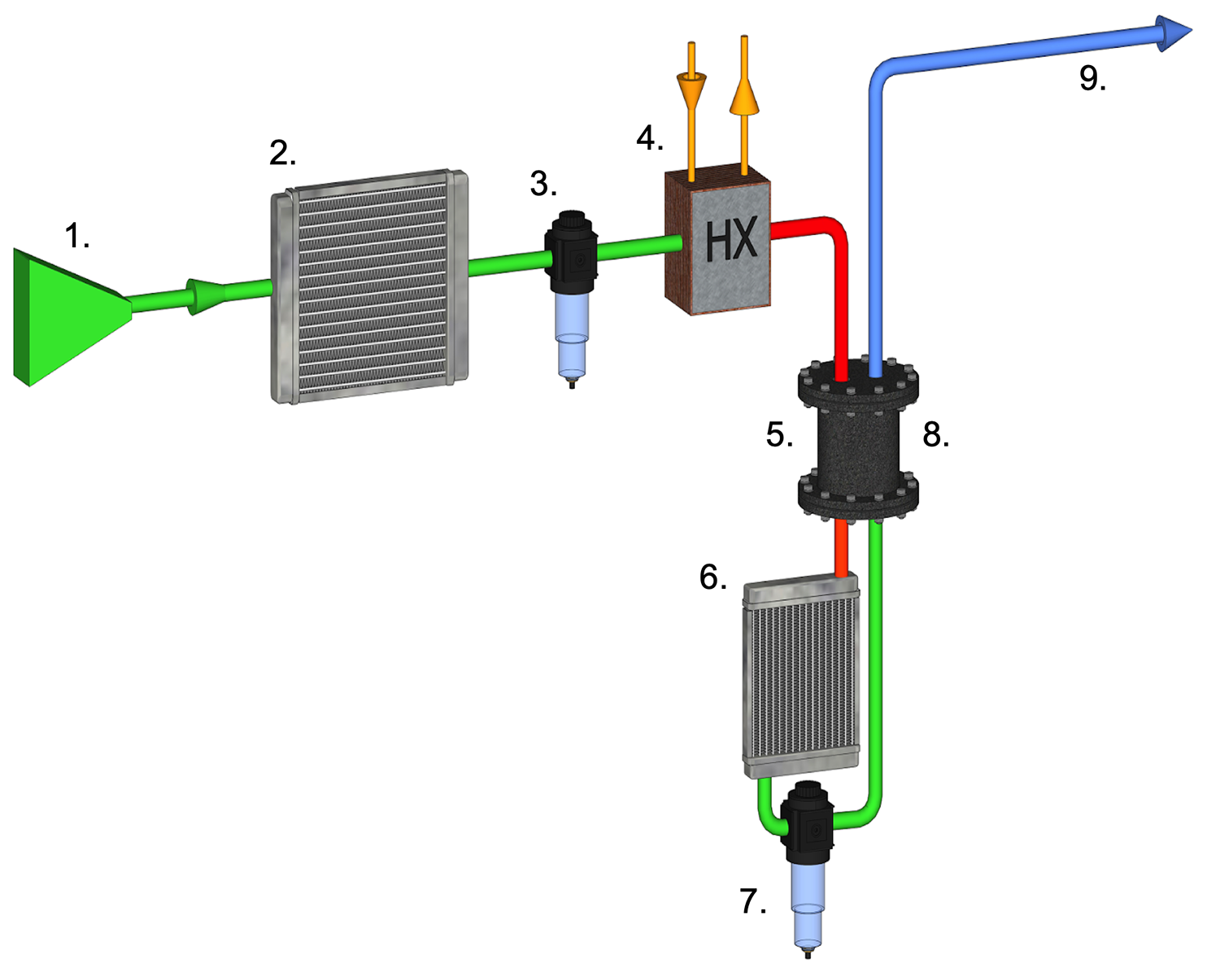

The unit has no refrigerant and only requires a heat exchanger in the compressor package in addition to the drum dryer.

The KDR E-Save Drum Dryer can be configured to work for zero dewpoint, and -20 °C applications.

The KDR E-Save Drum Dryer is very compact and can be installed both vertically and horizontally in a compressor package. It is ideal for small compressors in the range of 2.2kw but is also suitable for large compressors up to 400kw.

Traditionally, drum dryers can’t be used for oil-flooded compressors as the operating temperature is not high enough. KDR’s system first cools the air and removes 87% of the moisture and reheats the air using waste heat from the compressor which makes the regeneration ultra dry. It is the only dryer of its kind on the market.

The KDR E-Save Drum Dryer can be purchased or licensed from KDR Compressors who have world-wide patent coverage.

There is no cheaper or as energy efficient option as the KDR E-Save Drum Dryer.