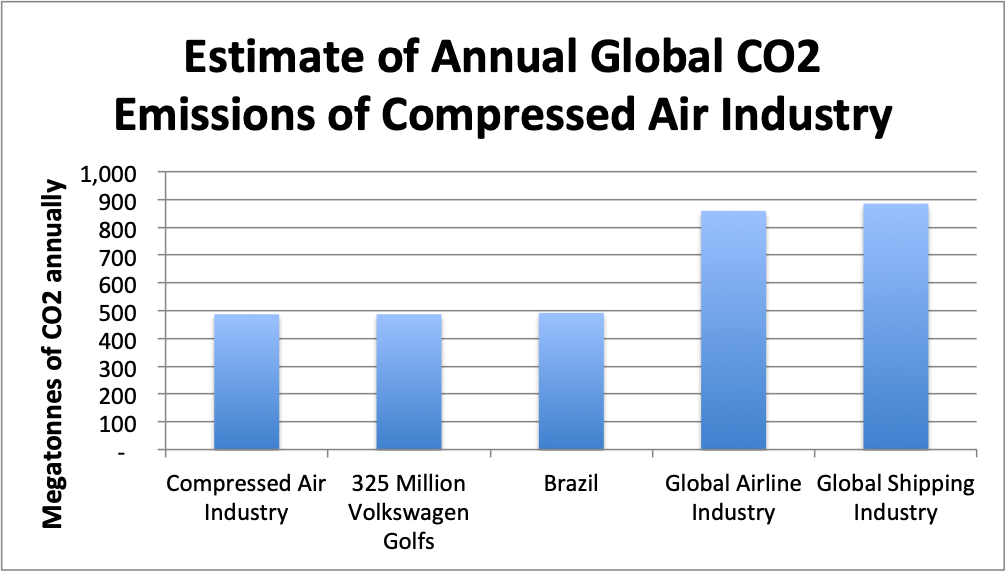

The compressed air industry is huge emitter of greenhouse gases. Its emissions are in the form the electrical power required to drive the compressors and the air treatment systems and also in the form of the refrigeration gases used in refrigeration air dryers.

The compressed air industry makes up approximately 10% of all industrial energy consumption. With each 100 HP having an annual impact of producing approx. 100 tonnes of greenhouse gases, the need to reduce the energy consumption of the compressed air industry has never been more important.

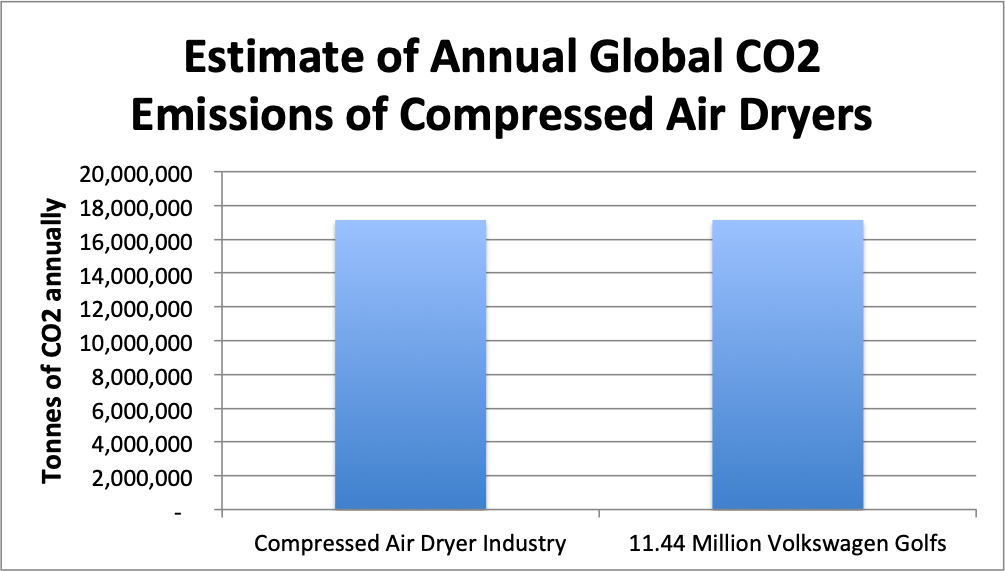

Compressed air dryer industry

It is estimated that the compressed air dryer industry globally through the electrical consumption of the dryers and the purge air required creates emissions equivalent 11.44 million Volkswagen Golfs.

Action on Climate Change

The impetuous for action on emissions is growing year by year. For many years the drive for change has come from scientific bodies, international accords (e.g. Kyoto Protocol) and from the governmental level. It is now clear that the next phase has begun with corporations now willing to take action on emissions (e.g. tech giant Bosch recently committed to be carbon neutral in 2020).

Our Commitment to Sustainability

At KDR Compressors we are committed to sustainability and doing our part to reduce emissions. As our dryer uses the heat of compression, it removes the need for electrical power and additionally it does not use any purge air. These factors allow our dryer to drastically reduce emissions of the user’s compressed air system.

Emissions Reductions of the KDR Rotary Drum Dryer

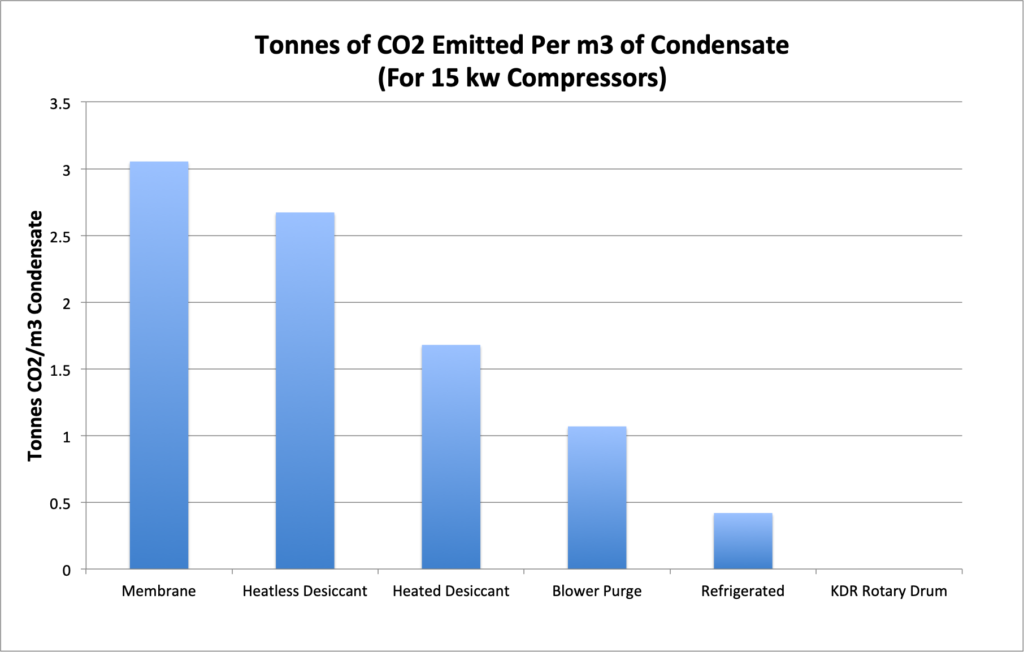

Dryer emissions for a 15 kw compressor

If we measure the tonnes of CO2 per m3 of condensate for dryers sized for a 15 kw compressor, then the membrane dryer becomes the most emissions intensive dryer due to a purge rate of 20%, emitting approx. 3 tonnes of CO2 per m3 of condensate produced. The membrane is closely followed by the heatless which emits approx. 2.65 tonnes of CO2 per m3 of condensate produced. The KDR Rotary Drum Dryer emits 0 tonnes of CO2.

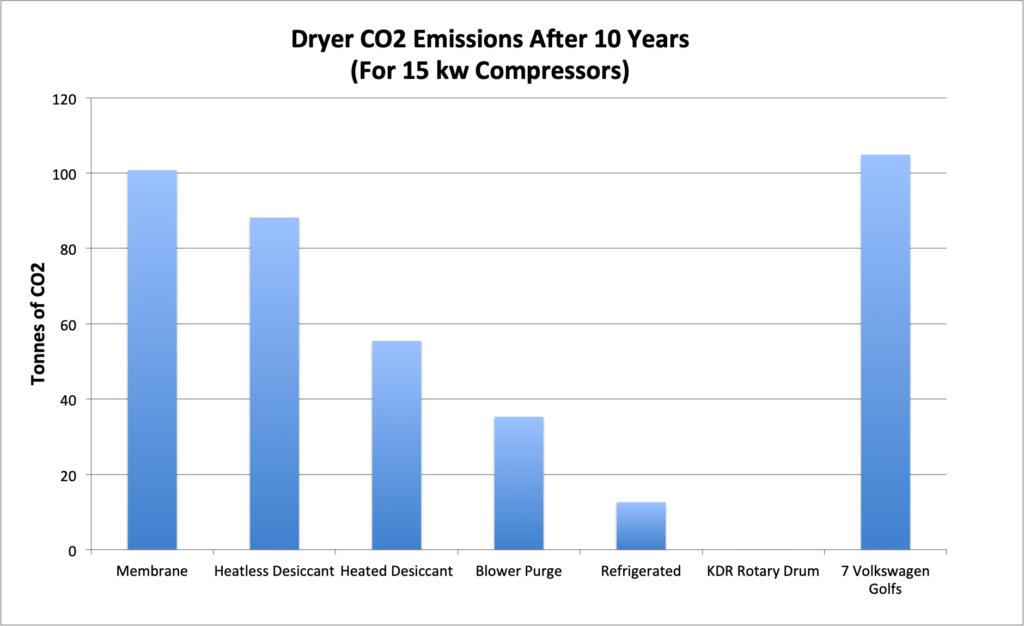

After 10 years the energy used to generate the purge air for the membrane will produce 100 tonnes of C02. This is the equivalent of almost 7 Volkswagen Golfs. Meanwhile, a KDR Rotary Drum Dryer would emit 0 tonnes over the same timeframe.

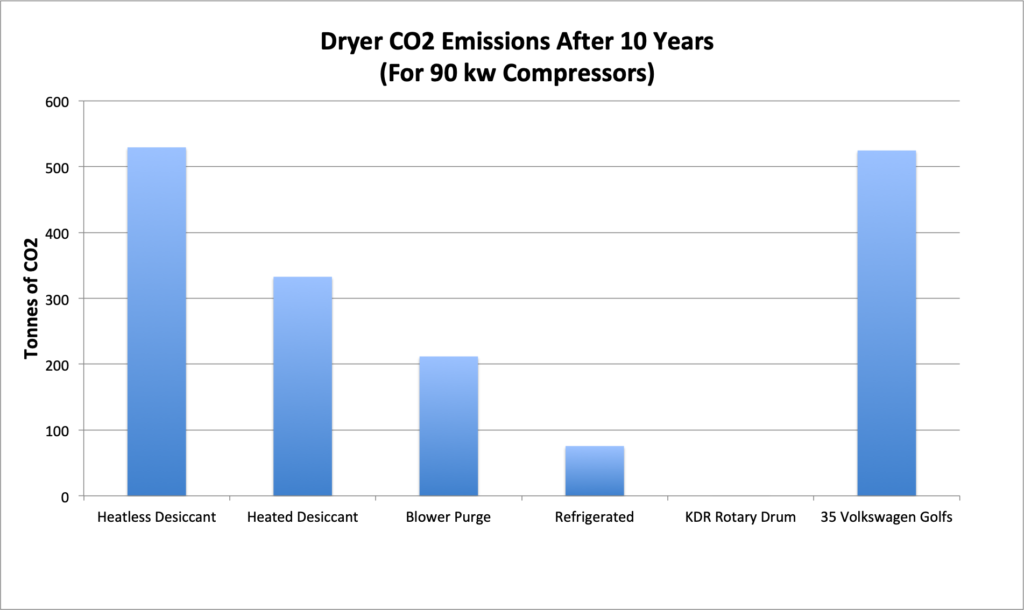

Dryer emissions for a 90 kw compressor

Our dryer delivers dry air without the harmful emissions. Compare this to the heatless dryer for a 90 kw compressor, which through the energy required to produce the purge air emits as much CO2 as 35 Volkswagen Golfs annually. Over 10 years this equates to approx. 525 tonnes of CO2.

The above graphs and calculations have been made on the following assumptions:

Emissions intensity of 560 gCO2/kwhr, equivalent to the German grid, France would have a lessor emissions intensity, Australia and China would have almost double the emissions intensity

Compressor run time of 6,000 hours annually

Global electricity consumption annually of 21,742 TWh

Electrical consumption of compressed air systems globally equal to 10% of total industrial electrical consumption