The KDR E-Save Hybrid Drum Dryer is ideal for anyone wanting -20 °C dewpoint without any purge loss.

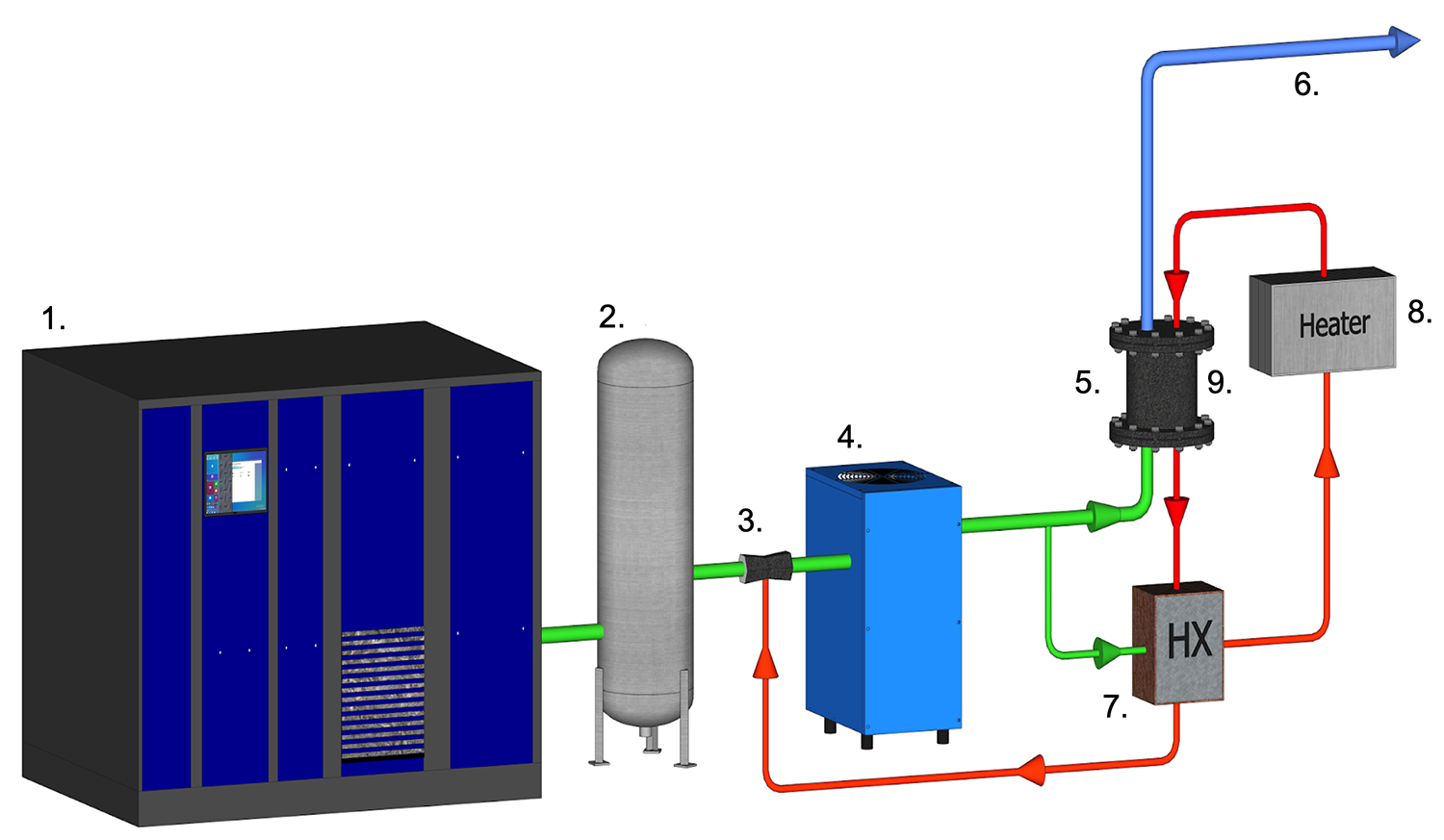

The first stage of the dryer system is a classic refrigeration dryer sized for 5 °C pressure dewpoint. The second stage is a KDR E-Save Drum Dryer.

The combination of the two systems produces:

● Constant -20 °C dewpoint (option for -40 °C dewpoint);

● Zero purge loss;

● Low energy consumption (2% refrigeration compressor, 1-2% for KDR E-Save Drum Dryer).

This hybrid system can be used on both oil-free and oil-flooded compressors. The savings in energy and purge loss make it more attractive than heated desiccant or traditional hybrid systems.

The KDR E-Save Hybrid Drum Dryer is smaller, lighter and more flexible to install than comparable systems. It has a simple standard piping between the first and second state, and does not require any alteration to the compressor system.

Environmentally friendly, Efficient, Energy saving, Easy to maintain & service.