The KDR E-Save Drum Dryer is ideal for OEM scroll compressor manufacturers.

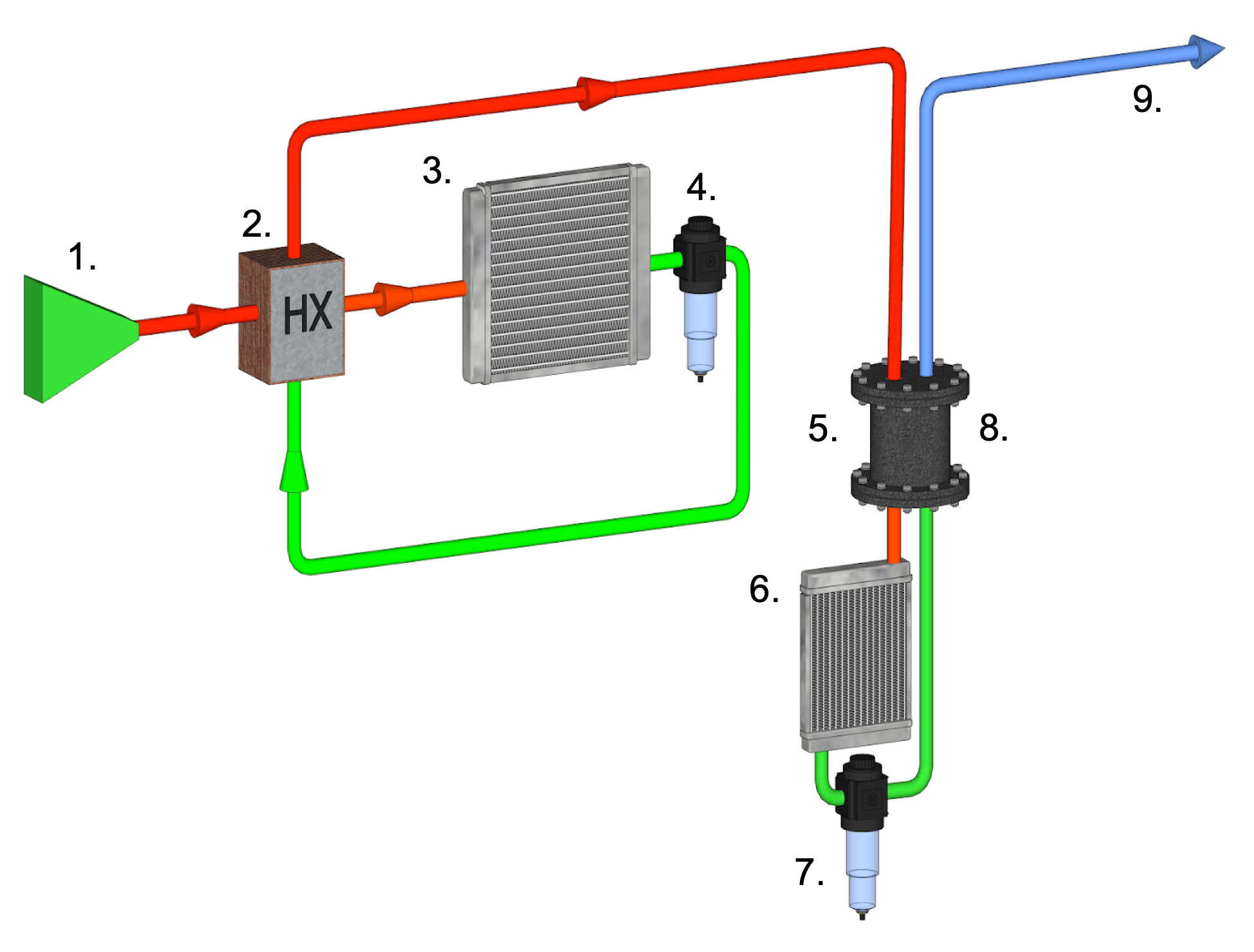

Using the waste heat of the hot scroll compressor the KDR E-Save Drum Dryer uses no power and is easy to install.

The unit has no refrigerant and only requires a heat exchanger in the compressor package in addition to the drum dryer.

The KDR E-Save Drum Dryer is far smaller and more compact than all other refrigerant and desiccant dryers on the market, making it the optimal dryer for packaging with scroll compressors.

The KDR E-Save Drum Dryer does not use any purge air, saving up to 15-20% of the valuable compressed air that a conventional heatless desiccant dryer would use.

The KDR E-Save Drum Dryer can be configured to work for zero dewpoint, and -20 °C applications.

The KDR E-Save Drum Dryer is very compact and can be installed both vertically and horizontally in a compressor package. It is ideal for scroll compressors of all sizes.

The KDR E-Save Drum Dryer can be purchased or licenced from KDR Compressors who have world-wide patent coverage.

The KDR E-Save Drum Dryer provides the best value and is the most energy efficient dryer on the market.

With a –20 °C dew point, zero purge air, easy installation, and its small and compact size, the KDR E-Save Drum Dryer is unmatched in its suitability for packaging with a scroll compressor.