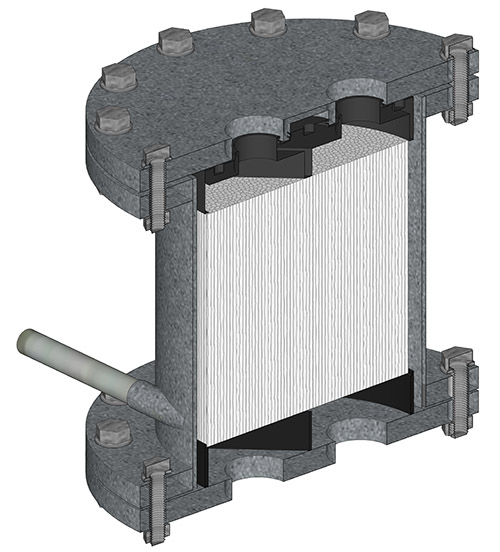

KDR’s patented innovation is a desiccant drum compressed air dryer for both oil-free and oil-flooded air compressors that uses no purge air, little or no power and be used for both built-in and stand-alone applications.

Its unique design means it can be built for small compressor applications (2KW and above) at low-cost. It is durable and quiet with none of the noisy venting of traditional twin tower desiccant dryers.

Unlike conventional refrigeration dryers the KDR dryer can be serviced by compressor service technicians and its unique changeable element will last 6000 hours. Compressor service technicians can change all parts of the unit. There is no refrigerant gas.

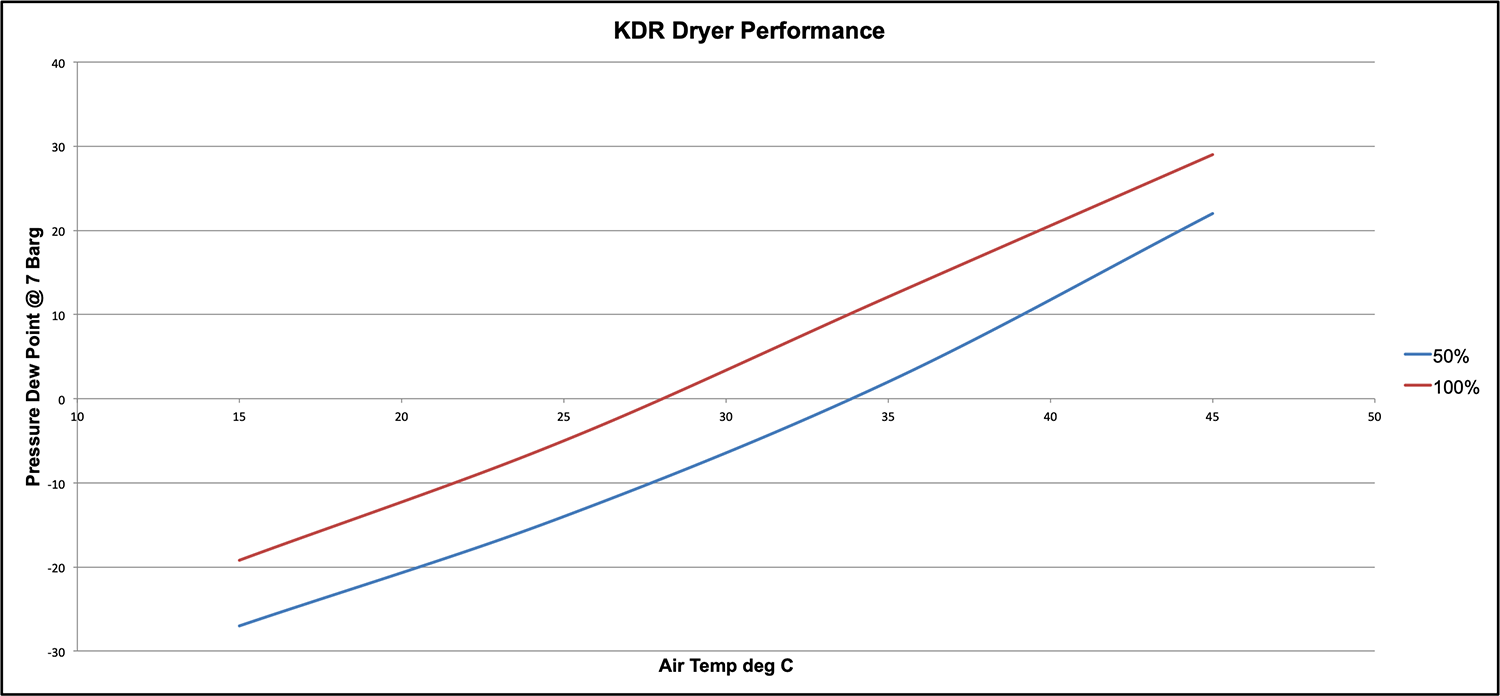

The KDR dryer as a built-in unit uses no power (working as a heat of compression dryer) whilst the stand-alone version has large power savings at part-load.

Being small and with few parts the KDR dryer is very cost competitive.