The KDR E-Save Drum Dryer is ideal for OEM compressor manufacturers.

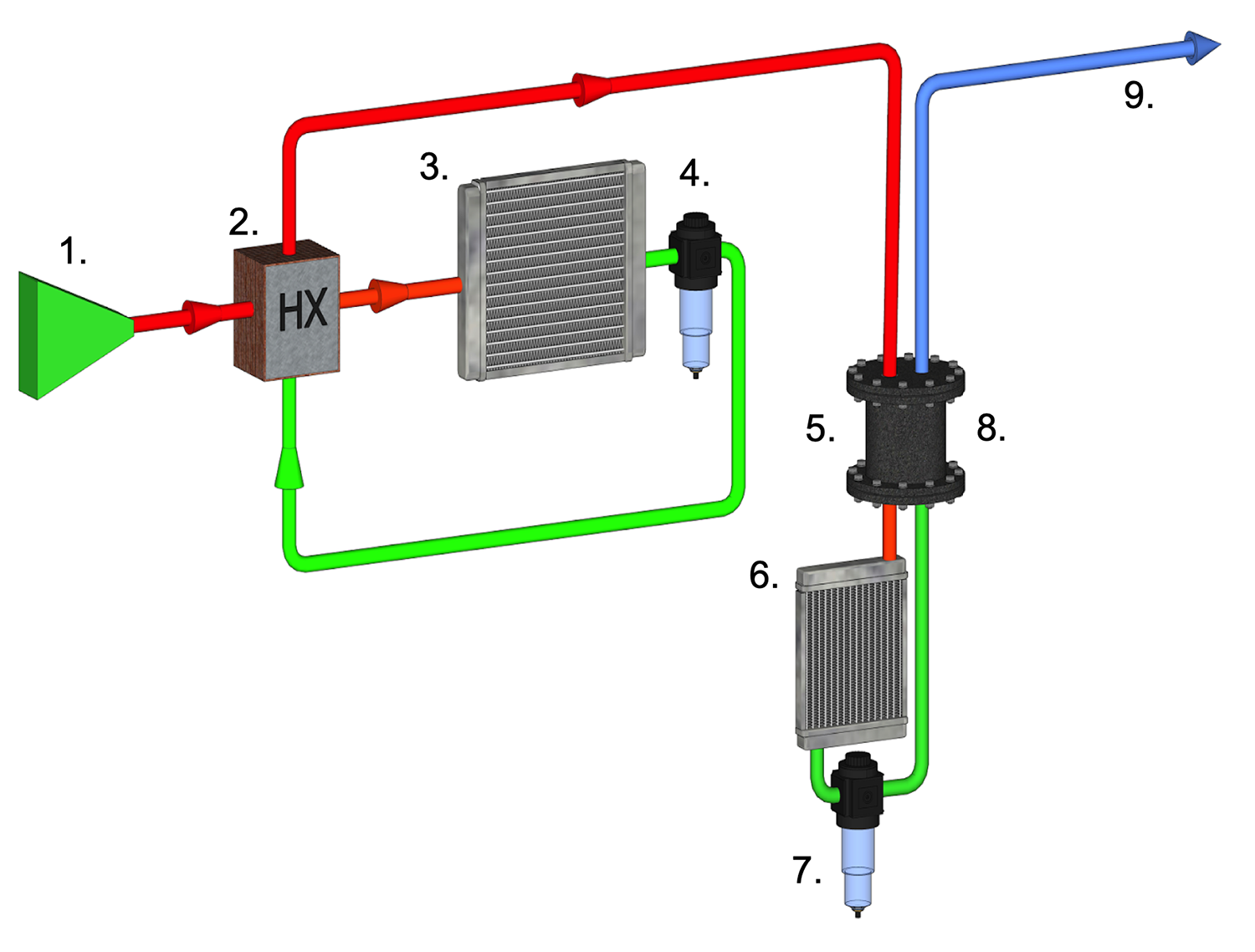

Using the waste heat of the compressor (oil-free compressors) the KDR E-Save Drum Dryer uses no power and is easy to install.

The unit has no refrigerant and only requires a heat exchanger in the compressor package in addition to the drum dryer.

The KDR E-Save Drum Dryer can be configured to work for zero dewpoint, and -20 °C applications.

The KDR E-Save Drum Dryer is very compact and can be installed both vertically and horizontally in a compressor package. It is ideal for small compressors in the range of 2.2kw but is also suitable for large compressors up to 400kw.

The KDR E-Save Drum Dryer can be purchased or licensed from KDR Compressors who have world-wide patent coverage.

There is no cheaper or as energy efficient option as the KDR E-Save Drum Dryer.